Plot No. 133-C, Tribhuvan Industrial Estate,

Road No. 8, Kathwada G.I.D.C., Ahmedabad - 382430 ,Gujarat (INDIA)

+91 7573884041

nsengineering@rediffmail.com

Plot No. 133-C, Tribhuvan Industrial Estate,

Road No. 8, Kathwada G.I.D.C., Ahmedabad - 382430 ,Gujarat (INDIA)

+91 7573884041

nsengineering@rediffmail.com

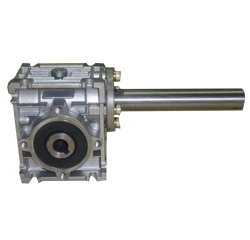

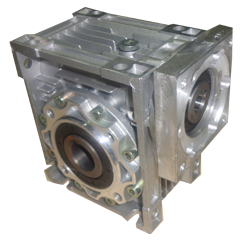

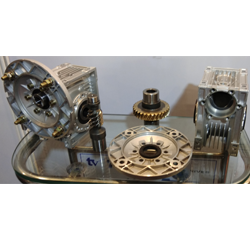

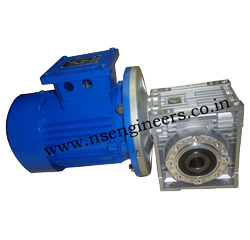

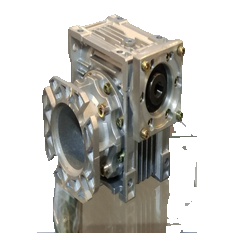

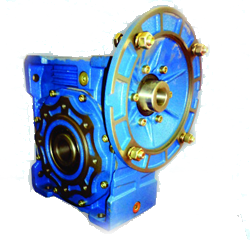

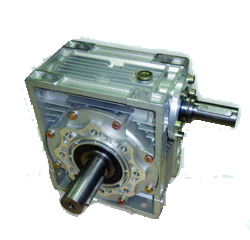

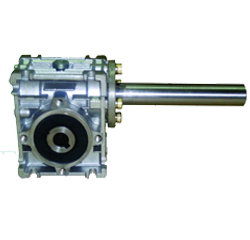

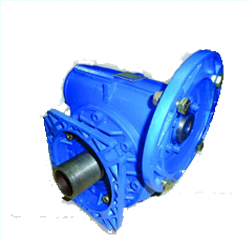

N. S. TECHNOCRATS PVT. LTD. is engaged in offering the best quality Aluminium Body Worm Gearbox to its customers. The use of the latest technology in manufacturing power transmission products makes us an explicit industrial forerunner in India. Our state of the art production methods ensure best quality products which are highly efficient and durable.

This mechanical speed variator machinery is designed to be mounted in several directions except the motor pointing up. Its efficient design to change drive direction to 90-degree makes it even more efficient. Features like easy to mount and low maintenance make it is a preferable choice for manufacturing industries. The easy to handle aluminum worm gearbox is built in a simple structure which can be used with electric motors for output speed reduction, large torque and good capability of enduring overload. This gearbox is an ideal solution for running two loads from one motor and highly serves the purpose of running machinery like conveyors, rotary table, and packaging machinery.

At N. S. TECHNOCRATS PVT. LTD., we constantly look towards making our products highly durable and thus cost-effective. Our massive production unit helps us to manufacture the best quality products within a limited period of time helping us serve our clients better.

| Model | I (RATIO) | B | H | |||||||||||||||

| Frame | KW | N | M | P | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| D (SHAFT DIA) | ||||||||||||||||||

| 30 | 63B5 | 0.12/0.18 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | - | - | - | 4 | 12.8 |

| 63B14 | 60 | 75 | 90 | |||||||||||||||

| 56B5 | 0.06/0.09 | 80 | 100 | 120 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | - | 3 | 10.4 | |

| 56B14 | 50 | 65 | 80 | |||||||||||||||

| 40 | 71B5 | 0.25/0.37 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | - | - | - | - | 5 | 16.3 |

| 71B14 | 70 | 85 | 105 | |||||||||||||||

| 63B5 | 0.12/0.18 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 4 | 12.8 | |

| 63B14 | 60 | 75 | 90 | |||||||||||||||

| 56B5 | 0.06/0.09 | 80 | 100 | 120 | - | - | - | - | - | - | - | 9 | 9 | 9 | 9 | 3 | 10.4 | |

| 50 | 80B5 | 0.55/0.75 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | - | - | - | - | - | 6 | 20.8 |

| 80B14 | 80 | 100 | 120 | |||||||||||||||

| 71B5 | 0.25/0.37 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | - | 5 | 16.3 | |

| 71B14 | 70 | 85 | 105 | |||||||||||||||

| 63B5 | 0.12/0.18 | 95 | 115 | 140 | - | - | - | - | - | - | 11 | 11 | 11 | 11 | 11 | 4 | 12.8 | |

| 63 | 90B5 | 1.1/1.5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | - | - | - | - | - | 8 | 26.3 |

| 90B14 | 95 | 115 | 140 | |||||||||||||||

| 80B5 | 0.55/0.75 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | - | - | 6 | 20.8 | |

| 80B14 | 80 | 100 | 120 | |||||||||||||||

| 71B5 | 0.25/0.37 | 110 | 130 | 160 | - | - | - | - | - | - | - | 14 | 14 | 14 | 14 | 5 | 16.3 | |

| 71B14 | 70 | 85 | 105 | |||||||||||||||

| 75 | 100/112B5 | 2.2/4 | 180 | 215 | 250 | 28 | 28 | 28 | - | - | - | - | - | - | - | - | 8 | 30.3 |

| 100/112B14 | 110 | 130 | 160 | |||||||||||||||

| 90B5 | 1.1/1.5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | - | - | - | - | 8 | 27.3 | |

| 90B14 | 95 | 100 | 120 | |||||||||||||||

| 80B5 | 0.55/0.75 | 130 | 165 | 200 | - | - | - | - | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 6 | 21.8 | |

| 80B14 | 80 | 100 | 120 | |||||||||||||||

| 71B5 | 0.25/0.37 | 110 | 130 | 160 | - | - | - | - | - | - | - | 14 | 14 | 14 | 14 | 5 | 16.3 | |

| 90 | 100/112B5 | 2.2/4 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | - | - | - | - | - | 8 | 30.3 |

| 100/112B14 | 110 | 130 | 160 | |||||||||||||||

| 90B5 | 1.1/1.5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | - | - | 8 | 27.3 | |

| 90B14 | 95 | 115 | 140 | |||||||||||||||

| 80B5 | 0.55/0.75 | 130 | 165 | 200 | - | - | - | - | - | 19 | 19 | 19 | 19 | 19 | 19 | 6 | 21.8 | |

| 80B14 | 80 | 100 | 120 | |||||||||||||||

| 110 | 132B5 | 5.5/7.5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | - | - | - | - | - | - | 10 | 40.8 | |

| 100/112B5 | 2.2/4 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | - | - | 8 | 31.3 | |

| 90B5 | 1.1/1.5 | 130 | 165 | 200 | - | - | - | - | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 8 | 27.3 | |

| 80B5 | 0.55/0.75 | 130 | 165 | 200 | - | - | - | - | - | - | - | - | - | 19 | 19 | 6 | 21.8 | |

| 130 | 132B5 | 5.5/7.5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | - | - | - | - | 10 | 40.8 |

| 100/112B5 | 2.2/4 | 180 | 215 | 250 | - | - | - | - | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 80 | 31.3 | |

| 90B5 | 1.1/1.5 | 130 | 165 | 200 | - | - | - | - | - | - | - | - | - | 24 | 24 | 80 | 27.3 | |

| Input | Size | i | n2(r/min) | M2(N-m) |

| 30 | 7.5 | 186 | 2.6 | |

| 25 | 10 | 140 | 3.4 | |

| 30 | 10 | 140 | 3.4 | |

| 25 | 15 | 93 | 4.9 | |

| 30 | 15 | 93 | 4.7 | |

| 25 | 20 | 70 | 6.1 | |

| 30 | 20 | 70 | 6 | |

| 30 | 25 | 56 | 7 | |

| 0.06 Kw | 25 | 30 | 47 | 8.2 |

| 0.08 Hp | 30 | 30 | 47 | 8 |

| 4 poles | 25 | 40 | 35 | 10.2 |

| 30 | 40 | 35 | 9.7 | |

| 25 | 50 | 28 | 11 | |

| 30 | 50 | 28 | 11.3 | |

| 40 | 50 | 28 | 12.7 | |

| 25 | 60 | 23 | 11 | |

| 30 | 60 | 23 | 12.5 | |

| 40 | 60 | 23 | 14.2 | |

| 30 | 80 | 18 | 12.5 | |

| 40 | 80 | 18 | 17 | |

| 40 | 100 | 14 | 19.2 | |

| 30 | 7.5 | 186 | 3.9 | |

| 25 | 10 | 140 | 5.1 | |

| 30 | 10 | 140 | 5 | |

| 25 | 15 | 93 | 7.3 | |

| 30 | 15 | 93 | 7.1 | |

| 25 | 20 | 70 | 9.2 | |

| 30 | 20 | 70 | 9 | |

| 0.09 Kw | 30 | 25 | 56 | 10.4 |

| 0.12 Hp | 25 | 30 | 47 | 12.3 |

| 4 poles | 30 | 30 | 47 | 12 |

| 25 | 40 | 35 | 13 | |

| 30 | 40 | 35 | 14.5 | |

| 30 | 50 | 28 | 16.9 | |

| 40 | 50 | 28 | 19 | |

| 30 | 60 | 23 | 16.9 | |

| 40 | 60 | 23 | 21.4 | |

| 40 | 80 | 18 | 25.5 | |

| 40 | 100 | 14 | 28.9 | |

| 30 | 7.5 | 187 | 5.2 | |

| 40 | 7.5 | 187 | 5.3 | |

| 30 | 10 | 140 | 6.7 | |

| 40 | 10 | 140 | 7 | |

| 30 | 15 | 93 | 9.5 | |

| 40 | 15 | 93 | 10.1 | |

| 30 | 20 | 70 | 12 | |

| 40 | 20 | 70 | 12.8 | |

| 30 | 25 | 56 | 13.9 | |

| 0.12 Kw | 40 | 25 | 56 | 15.3 |

| 0.16 Hp | 30 | 30 | 47 | 16 |

| 4 poles | 40 | 30 | 47 | 17.2 |

| 30 | 40 | 35 | 17 | |

| 40 | 40 | 35 | 21.3 | |

| 50 | 40 | 35 | 21.9 | |

| 40 | 50 | 28 | 25.4 | |

| 40 | 50 | 28 | 25.8 | |

| 40 | 60 | 23 | 28.5 | |

| 50 | 60 | 23 | 29 | |

| 40 | 80 | 18 | 34.1 | |

| 50 | 80 | 18 | 34.7 | |

| 50 | 100 | 14 | 40.1 | |

| 30 | 7.5 | 187 | 8 | |

| 40 | 7.5 | 187 | 8 | |

| 30 | 10 | 140 | 10 | |

| 40 | 10 | 140 | 10 | |

| 30 | 15 | 93 | 14 | |

| 40 | 15 | 93 | 15 | |

| 30 | 20 | 70 | 18 | |

| 40 | 20 | 70 | 19 | |

| 0.18 Kw | 30 | 25 | 56 | 20 |

| 0.25 Hp | 40 | 25 | 56 | 23 |

| 4 poles | 40 | 30 | 47 | 26 |

| 50 | 40 | 35 | 32 | |

| 40 | 40 | 35 | 32 | |

| 40 | 50 | 28 | 38 | |

| 50 | 50 | 28 | 38 | |

| 50 | 50 | 28 | 38 | |

| 50 | 60 | 23 | 34 | |

| 50 | 80 | 18 | 53 | |

| 50 | 100 | 14 | 55 | |

| 40 | 7.5 | 187 | 11 | |

| 50 | 7.5 | 187 | 11 | |

| 40 | 10 | 140 | 14 | |

| 50 | 10 | 140 | 14 | |

| 40 | 15 | 94 | 20 | |

| 50 | 15 | 94 | 21 | |

| 40 | 20 | 70 | 26 | |

| 50 | 20 | 70 | 26 | |

| 0.25 Kw | 40 | 25 | 56 | 31 |

| 0.33 Hp | 50 | 25 | 56 | 32 |

| 4 poles | 40 | 30 | 47 | 36 |

| 50 | 30 | 47 | 36 | |

| 40 | 40 | 35 | 44 | |

| 50 | 40 | 35 | 45 | |

| 50 | 50 | 28 | 53 | |

| 50 | 60 | 23.3 | 60 | |

| 50 | 80 | 18 | 65 | |

| 63 | 80 | 18 | 77 | |

| 63 | 100 | 14 | 85 | |

| 40 | 7.5 | 187 | 16 | |

| 50 | 7.5 | 187 | 16 | |

| 40 | 10 | 140 | 21 | |

| 50 | 10 | 140 | 21 | |

| 40 | 15 | 93 | 30 | |

| 40 | 20 | 70 | 39 | |

| 0.37 Kw | 50 | 20 | 70 | 39 |

| 0.50 Hp | 50 | 25 | 56 | 47 |

| 4 poles | 50 | 30 | 47 | 54 |

| 50 | 40 | 35 | 66 | |

| 63 | 40 | 35 | 70 | |

| 50 | 50 | 28 | 73 | |

| 63 | 50 | 28 | 83 | |

| 63 | 60 | 23 | 95 | |

| 63 | 80 | 18 | 114 | |

| 40 | 7.5 | 186 | 24.5 | |

| 50 | 7.5 | 186 | 25 | |

| 40 | 10 | 140 | 32 | |

| 50 | 10 | 140 | 32 | |

| 50 | 15 | 94 | 46 | |

| 63 | 15 | 94 | 46 | |

| 50 | 20 | 70 | 59 | |

| 0.55 Kw | 63 | 20 | 70 | 60 |

| 0.75 Hp | 63 | 25 | 56 | 72 |

| 4 poles | 63 | 30 | 47 | 80 |

| 63 | 40 | 35 | 104 | |

| 75 | 40 | 35 | 108 | |

| 63 | 50 | 28 | 123 | |

| 75 | 50 | 28 | 129 | |

| 75 | 60 | 23 | 146 | |

| 75 | 80 | 17 | 180 | |

| 75 | 100 | 14 | 180 | |

| 50 | 7.5 | 186 | 34 | |

| 63 | 7.5 | 186 | 33 | |

| 50 | 10 | 140 | 44 | |

| 63 | 10 | 140 | 44 | |

| 50 | 15 | 94 | 63 | |

| 63 | 15 | 94 | 63 | |

| 63 | 20 | 70 | 82 | |

| 63 | 25 | 56 | 99 | |

| 0.75 Kw | 63 | 30 | 47 | 109 |

| 1.00 Hp | 75 | 30 | 47 | 116 |

| 4 poles | 63 | 40 | 35 | 143 |

| 75 | 40 | 35 | 147 | |

| 75 | 50 | 28 | 176 | |

| 90 | 50 | 28 | 184 | |

| 75 | 60 | 23 | 200 | |

| 90 | 60 | 23 | 212 | |

| 90 | 80 | 17 | 257 | |

| 90 | 100 | 14 | 270 | |

| 63 | 7.5 | 186 | 49 | |

| 75 | 7.5 | 186 | 49 | |

| 63 | 10 | 140 | 65 | |

| 75 | 10 | 140 | 66 | |

| 63 | 15 | 93 | 93 | |

| 75 | 15 | 93 | 95 | |

| 63 | 20 | 70 | 121 | |

| 1.1 Kw | 75 | 20 | 70 | 122 |

| 1.5 Hp | 75 | 25 | 56 | 149 |

| 4 poles | 75 | 30 | 46 | 170 |

| 75 | 40 | 35 | 216 | |

| 90 | 40 | 35 | 225 | |

| 90 | 50 | 28 | 271 | |

| 90 | 60 | 23 | 311 | |

| 110 | 60 | 23 | 324 | |

| 110 | 80 | 17 | 410 | |

| 110 | 100 | 14 | 460 | |

| 75 | 7.5 | 186 | 67 | |

| 75 | 10 | 140 | 90 | |

| 75 | 15 | 93 | 130 | |

| 75 | 20 | 70 | 167 | |

| 75 | 25 | 56 | 200 | |

| 90 | 25 | 56 | 209 | |

| 1.5 Kw | 75 | 30 | 47 | 230 |

| 2.0 Hp | 90 | 30 | 47 | 236 |

| 4 poles | 90 | 40 | 35 | 306 |

| 90 | 50 | 28 | 369 | |

| 110 | 50 | 28 | 375 | |

| 110 | 60 | 23 | 442 | |

| 110 | 80 | 17 | 790 | |

| 130 | 80 | 17 | 547 | |

| 130 | 100 | 14 | 652 | |

| 90 | 7.5 | 187 | 101 | |

| 110 | 7.5 | 187 | 101 | |

| 90 | 10 | 140 | 133 | |

| 110 | 10 | 140 | 133 | |

| 90 | 15 | 94 | 193 | |

| 110 | 15 | 94 | 193 | |

| 90 | 20 | 70 | 251 | |

| 2.2 Kw | 110 | 20 | 70 | 256 |

| 3.0 Hp | 90 | 25 | 56 | 307 |

| 4 poles | 110 | 25 | 56 | 316 |

| 90 | 30 | 46 | 346 | |

| 110 | 30 | 46 | 355 | |

| 110 | 40 | 35 | 462 | |

| 110 | 50 | 28 | 550 | |

| 130 | 50 | 28 | 566 | |

| 130 | 60 | 23 | 650 | |

| 130 | 80 | 17 | 803 | |

| 110 | 7.5 | 187 | 138 | |

| 110 | 10 | 140 | 182 | |

| 110 | 15 | 94 | 263 | |

| 3.0 Kw | 110 | 20 | 70 | 348 |

| 4.0 Hp | 110 | 25 | 56 | 430 |

| 4 Poles | 110 | 30 | 46.7 | 484 |

| 110 | 40 | 35 | 631 | |

| 130 | 40 | 35 | 638 | |

| 130 | 50 | 28 | 767 | |

| 130 | 60 | 23 | 884 | |

| 110 | 7.5 | 186 | 184 | |

| 130 | 7.5 | 186 | 186 | |

| 110 | 10 | 140 | 243 | |

| 130 | 10 | 140 | 243 | |

| 110 | 15 | 93 | 352 | |

| 4.0 Kw | 130 | 15 | 93 | 357 |

| 5.0 Hp | 110 | 20 | 70 | 464 |

| 4 Poles | 130 | 20 | 70 | 466 |

| 110 | 25 | 56 | 573 | |

| 130 | 25 | 56 | 573 | |

| 110 | 30 | 47 | 646 | |

| 130 | 30 | 47 | 655 | |

| 110 | 40 | 35 | 850 | |

| 130 | 50 | 28 | 1023 | |

| 110 | 7.5 | 186 | 253 | |

| 130 | 7.5 | 186 | 256 | |

| 110 | 10 | 140 | 334 | |

| 5.5 Kw | 130 | 10 | 140 | 334 |

| 7.5 Hp | 110 | 15 | 94 | 484 |

| 4 Poles | 130 | 15 | 94 | 490 |

| 130 | 20 | 70 | 645 | |

| 130 | 25 | 56 | 788 | |

| 130 | 30 | 47 | 900 | |

| 110 | 7.5 | 186 | 345 | |

| 7.5 Kw | 130 | 7.5 | 186 | 349 |

| 10 Hp | 110 | 10 | 140 | 455 |

| 4 Poles | 130 | 10 | 140 | 455 |

| 130 | 15 | 94 | 667 |

| Size | A | C | D | E | F | G | H | I | L | M | N | O | P | Q | R | S | V | K |

| Model | ||||||||||||||||||

| 30 | 54 | 80 | 14 | 97 | 32 | 63 | 40 | 30 | 56 | 65 | 55 | 6.5 | 75 | 44 | 57 | 5.5 | 27 | 44 |

| 40 | 70 | 100 | 18 (19) | 121 | 43 | 70 | 50 | 40 | 71 | 75 | 60 | 7 | 85 | 55 | 71 | 6.5 | 35 | 60 |

| 50 | 80 | 120 | 25 | 144 | 49 | 80 | 60 | 50 | 85 | 85 | 70 | 8.5 | 100 | 64 | 84 | 7 | 40 | 70 |

| 63 | 100 | 144 | 28 (28) | 174 | 67 | 95 | 72 | 63 | 103 | 95 | 80 | 8.5 | 110 | 80 | 102 | 8 | 50 | 85 |

| 75 | 120 | 174 | 28 | 205 | 72 | 112.5 | 86 | 75 | 113 | 115 | 95 | 11 | 140 | 93 | 119 | 10 | 60 | 90 |

| 90 | 140 | 208 | 35 | 238 | 73 | 130 | 103 | 90 | 130 | 130 | 110 | 13 | 160 | 102 | 135 | 11 | 70 | 100 |

| 110 | 170 | 252.5 | 42 | 294 | - | 160 | 127.5 | 110 | 142 | 165 | 130 | 14 | 200 | 125 | 167.5 | 15 | 85 | 115 |

| 130 | 200 | 292.5 | 45 | 334 | - | 180 | 147.5 | 130 | 154 | 215 | 180 | 16 | 250 | 140 | 187.5 | 15 | 100 | 120 |

| Size | G2 | N1 | KA | KB | KC | KE | A | KM | KN | KO | KP | KQ | D | B | T1 | X | Y | |

| Model | ||||||||||||||||||

| 30 | 50 | 29 | 54.5 | 6 | 4 | M6x11(n.4) | 0░ | 68 | 50 | 6.5(4/90░) | 80 | 70 | 9 | 5 | 16.3 | 3 | 10.2 | |

| 40 | 60 | 36.5 | 67 | 7 | 4 | M6x8(n.4) | 45░ | 87 | 60 | 9(4/90░) | 110 | 95 | 11 | 6 | 20.8 (21.8) | 4 | 12.5 | |

| 50 | 74 | 43.5 | 90 | 9 | 5 | M8x10(n.4) | 45░ | 90 | 70 | 11(4/90░) | 125 | 110 | 14 | 8 | 28.3 | 5 | 16 | |

| 63 | 90 | 53 | 97 | 10 | 6 | M8x14(m.4) | 45░ | 150 | 115 | 11(4/90░) | 180 | 142 | 19 | 8 | 28.3 (31.3) | 6 | 21.5 | |

| 75 | 105 | 57 | 111 | 13 | 6 | M8x14(n.8) | 45░ | 165 | 130 | 14(4/90░) | 200 | 170 | 24 | 8 | 31.3 | 8 | 27 | |

| 90 | 125 | 67 | 111 | 13 | 6 | M10x18(n.8) | 45░ | 175 | 152 | 14(4/90░) | 210 | 200 | 24 | 10 | 38.3 | 8 | 27 | |

| 110 | 142 | 74 | 139 | 15 | 6 | M10x18(n.8) | 45░ | 220 | 170 | 14(8/45░) | 270 | 250 | 28 | 12 | 45.3 | 8 | 31 | |

| 130 | 162 | 80.5 | 140 | 15 | 6 | M12x26(n.8) | 45░ | 255 | 180 | 16(8/45░) | 320 | 290 | 30 | 14 | 48.8 | 8 | 33 | |

| Size | 1 | 2 | 3 | 4 | 5 | 6 | |||||||

| Motor Input Power(Kw) | 0.18 | 0.25 | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | |

| Motor Poles | (1400r/min) 4 poles | ||||||||||||

| Types | Output Speed | - | Maximum output Torque Allowed (N.m) | ||||||||||

| Basic Type Model: NSVF | 190-950 | 2.5-1.6 | 3.5-1.8 | 5.1-2.7 | 8-4 | 11-5.4 | 15.3-8 | 21-11 | 30.6-16 | 42-22 | 59-29 | 77-40 | 105-54 |

| With One Pair of Gear Speed Reducer Model: NSVR | 100-500 | - | 6.5-3.4 | 9.5-5 | 14.2-7.4 | 20-10 | 29.2-15 | 40-20 | 58-30 | 80-40 | 104-54 | 143-74 | 200-101 |

| 80-400 | - | 8-4.2 | 12.3-6.2 | 17.5-9.3 | 25-12.5 | 37-18.5 | 50-52 | 71-37 | 100.50.5 | 130-67 | 180-93 | 2445-126 | |

| 60-300 | - | 11-5.6 | 15.8-8.3 | 24.5-13 | 33.2-16.8 | 50-21.7 | 65-34 | 98-50 | 134-67.5 | 173-90 | 240-124 | 330-168 | |

| 40-200 | 14-6.2 | 16-8.4 | 24-12.5 | 34.5-18.5 | 50-25 | 73-37 | 100-50.5 | 147-74 | 200-201 | 256-135 | 380-190 | 190-253 | |

| With Two Pair of Gear Speed Reducer Model: NSVR | 30-150 | - | - | - | - | - | - | - | 186-100 | 267-132 | 356-176 | 490-242 | 668-300 |

| 28-140 | - | - | - | 52-26 | 70-35.4 | 105-52 | 143-71 | - | - | - | - | - | |

| 25-125 | - | 25-13 | 39-20 | - | - | - | - | - | - | - | - | - | |

| 20-100 | - | - | - | - | - | - | - | 294-145 | 401-198 | 515-264 | 735-363 | 1002-495 | |

| 18-90 | - | - | - | 81-40 | 100-55 | - | - | - | - | - | - | - | |

| 15-75 | - | 42-22 | 65-32.6 | - | - | 196-97 | 255-132 | - | - | - | - | - | |

| 13-65 | - | - | - | 113-56 | 150-76 | - | - | - | - | - | - | - | |

| 9-45 | - | 65-37 | 105-54 | - | - | - | - | - | - | - | - | - | |

| 8-40 | - | - | - | 182-91 | 250-124 | - | - | - | - | - | - | - | |

| 6.5-32.5 | - | - | - | 225-112 | 300-152 | - | - | - | - | - | - | - | |

| With Three Pair of Gear Speed Reducer Model: NSVR | 4.7-23.5 | - | - | 204-102 | 292-150 | 426-207 | 603-303 | 795-413 | - | - | - | - | - |

| 2-10 | - | - | - | 426-356 | 426 | - | - | - | - | - | - | - | |

| Size Of Single Extension & Double Extension | |||||||

| Model | L | L1 | B | B1 | G1 | F | M XL2 |

| 30 | 128 | 95.5 | 32.5 | 30 | 63 | 14 | M6 X16 |

| 40 | 164 | 121 | 43 | 40 | 78 | 19 | M6 X16 |

| 50 | 199 | 145.5 | 53.5 | 50 | 92 | 25 | M8 X16 |

| 63 | 219 | 165.5 | 53.5 | 50 | 112 | 25 | M8 X16 |

| 75 | 246 | 183 | 63 | 60 | 120 | 28 | M10 X16 |

| 90 | 309 | 224.5 | 84.5 | 80 | 140 | 35 | M12 X24 |

| 110 | 324 | 239.5 | 84.5 | 80 | 155 | 42 | M12 X24 |

| 130 | 340 | 255 | 85 | 80 | 170 | 45 | M12 X24 |

| Double Extension Worm Shaft | |||||||

| Model | G2 | F | b2 | b | t | ||

| 30 | 45 | 9 | 20 | 3 | 10.2 | ||

| 40 | 53 | 11 | 23 | 4 | 12.5 | ||

| 50 | 64 | 14 | 30 | 5 | 16 | ||

| 63 | 75 | 19 | 40 | 6 | 21.5 | ||

| 75 | 90 | 24 | 50 | 8 | 27 | ||

| 90 | 108 | 24 | 50 | 8 | 27 | ||

| 110 | 135 | 28 | 60 | 8 | 31 | ||

| 130 | 155 | 30 | 80 | 8 | 31 | ||

| Model | i | n2 | kW1 | M2 | i1 | i2 |

| 30/40 | 300 | 4.7 | 0.08 | 45 | 10 | 30 |

| 400 | 3.5 | 0.06 | 41 | 10 | 40 | |

| 500 | 2.8 | 0.04 | 47 | 20 | 25 | |

| 600 | 2.3 | 0.04 | 45 | 20 | 30 | |

| 750 | 1.9 | 0.03 | 45 | 25 | 30 | |

| 900 | 1.6 | 0.02 | 45 | 30 | 30 | |

| 1200 | 1.2 | 0.02 | 41 | 30 | 40 | |

| 1500 | 0.93 | 0.02 | 45 | 50 | 30 | |

| 1800 | 0.78 | 0.01 | 45 | 60 | 30 | |

| 2400 | 0.58 | 0.01 | 41 | 60 | 40 | |

| 3200 | 0.47 | 0.01 | 41 | 80 | 40 | |

| 4000 | 0.35 | 0.01 | 33 | 50 | 80 | |

| 5000 | 0.28 | 0.01 | 29 | 50 | 100 | |

| 40/50 | 300 | 4.7 | 0.01 | 84 | 10 | 30 |

| 400 | 3.5 | 0.01 | 76 | 10 | 40 | |

| 500 | 2.8 | 0.09 | 73 | 10 | 50 | |

| 600 | 2.3 | 0.08 | 84 | 20 | 30 | |

| 750 | 1.9 | 0.07 | 84 | 25 | 30 | |

| 900 | 1.6 | 0.06 | 84 | 30 | 30 | |

| 1200 | 1.2 | 0.04 | 76 | 30 | 40 | |

| 1500 | 0.93 | 0.04 | 84 | 50 | 30 | |

| 1800 | 0.78 | 0.04 | 84 | 60 | 30 | |

| 2400 | 0.58 | 0.03 | 76 | 60 | 40 | |

| 3000 | 0.47 | 0.02 | 73 | 60 | 50 | |

| 4000 | 0.35 | 0.02 | 65 | 50 | 80 | |

| 4800 | 0.28 | 0.02 | 65 | 60 | 80 | |

| 40/63 | 300 | 4.7 | 0.15 | 160 | 10 | 30 |

| 400 | 3.5 | 0.24 | 145 | 10 | 40 | |

| 500 | 2.8 | 0.19 | 135 | 10 | 50 | |

| 600 | 2.3 | 0.15 | 145 | 15 | 40 | |

| 750 | 1.9 | 0.13 | 135 | 15 | 50 | |

| 900 | 1.6 | 0.11 | 130 | 15 | 60 | |

| 1200 | 1.2 | 0.09 | 145 | 30 | 40 | |

| 1500 | 0.93 | 0.08 | 35 | 30 | 50 | |

| 1800 | 0.78 | 0.06 | 130 | 30 | 60 | |

| 2400 | 0.58 | 0.05 | 145 | 60 | 40 | |

| 3000 | 0.47 | 0.04 | 135 | 60 | 50 | |

| 4000 | 0.35 | 0.03 | 122 | 50 | 80 | |

| 50/75 | 300 | 4.7 | 0.36 | 230 | 10 | 30 |

| 400 | 3.5 | 0.27 | 220 | 10 | 40 | |

| 500 | 2.8 | 0.21 | 210 | 10 | 50 | |

| 600 | 2.3 | 0.19 | 230 | 20 | 30 | |

| 750 | 1.9 | 0.16 | 230 | 25 | 30 | |

| 900 | 1.6 | 0.14 | 230 | 30 | 30 | |

| 1220 | 1.2 | 0.11 | 220 | 30 | 40 | |

| 1500 | 0.93 | 0.01 | 230 | 50 | 30 | |

| 1800 | 0.78 | 0.09 | 230 | 60 | 30 | |

| 2400 | 0.58 | 0.07 | 220 | 60 | 40 | |

| 3000 | 0.47 | 0.05 | 210 | 60 | 50 | |

| 4000 | 0.35 | 0.04 | 190 | 50 | 80 | |

| 50/90 | 300 | 4.7 | 0.56 | 610 | 10 | 30 |

| 400 | 3.5 | 0.43 | 610 | 10 | 40 | |

| 500 | 2.8 | 0.34 | 560 | 10 | 50 | |

| 600 | 2.3 | 0.3 | 610 | 20 | 30 | |

| 750 | 1.9 | 0.23 | 560 | 25 | 30 | |

| 900 | 1.6 | 0.19 | 505 | 30 | 30 | |

| 1200 | 1.2 | 0.17 | 610 | 30 | 40 | |

| 1500 | 0.93 | 0.14 | 560 | 50 | 30 | |

| 1800 | 0.78 | 0.11 | 505 | 60 | 30 | |

| 2400 | 0.58 | 0.11 | 610 | 60 | 40 | |

| 3000 | 0.47 | 0.08 | 560 | 60 | 50 | |

| 4000 | 0.35 | 0.08 | 460 | 50 | 80 | |

| 5000 | 0.28 | 0.06 | 410 | 50 | 100 | |

| 63/90 | 300 | 4.7 | 0.56 | 610 | 10 | 30 |

| 400 | 3.5 | 0.43 | 610 | 10 | 40 | |

| 500 | 2.8 | 0.34 | 560 | 10 | 50 | |

| 600 | 2.3 | 0.3 | 610 | 20 | 30 | |

| 750 | 1.9 | 0.23 | 560 | 25 | 30 | |

| 900 | 1.6 | 0.19 | 505 | 30 | 30 | |

| 1220 | 1.2 | 0.17 | 610 | 30 | 40 | |

| 1500 | 0.93 | 0.14 | 560 | 50 | 30 | |

| 1800 | 0.78 | 0.11 | 505 | 60 | 30 | |

| 2400 | 0.58 | 0.11 | 610 | 60 | 40 | |

| 3000 | 0.47 | 0.08 | 560 | 60 | 50 | |

| 4000 | 0.35 | 0.08 | 460 | 50 | 80 | |

| 5000 | 0.28 | 0.06 | 410 | 50 | 100 | |

| 63/110 | 300 | 4.7 | 0.95 | 630 | 10 | |

| 400 | 3.5 | 0.96 | 610 | 10 | 30 | |

| 500 | 2.8 | 0.56 | 600 | 10 | 40 | |

| 600 | 2.3 | 0.48 | 610 | 15 | 50 | |

| 750 | 1.9 | 0.43 | 630 | 25 | 40 | |

| 900 | 1.6 | 0.38 | 630 | 30 | 30 | |

| 1200 | 1.2 | 0.27 | 610 | 30 | 30 | |

| 1500 | 0.93 | 0.26 | 630 | 50 | 40 | |

| 1800 | 0.78 | 0.23 | 630 | 60 | 30 | |

| 2400 | 0.58 | 0.17 | 610 | 60 | 30 | |

| 3000 | 0.47 | 0.14 | 600 | 60 | 40 | |

| 4000 | 0.35 | 0.12 | 490 | 50 | 80 | |

| 4800 | 0.28 | 0.09 | 460 | 50 | 100 | |

| 75/130 | 300 | 4.7 | 1.48 | 1040 | 10 | 30 |

| 400 | 3.5 | 1.09 | 1050 | 10 | 40 | |

| 500 | 2.8 | 0.86 | 980 | 10 | 50 | |

| 600 | 2.3 | 0.76 | 1050 | 15 | 40 | |

| 750 | 1.9 | 0.66 | 1040 | 25 | 30 | |

| 900 | 1.6 | 0.58 | 1040 | 30 | 30 | |

| 1200 | 1.2 | 0.43 | 1050 | 30 | 40 | |

| 1500 | 0.93 | 0.39 | 1040 | 50 | 30 | |

| 1800 | 0.78 | 0.35 | 1040 | 60 | 30 | |

| 2400 | 0.58 | 0.25 | 1050 | 60 | 40 | |

| 3000 | 0.47 | 0.2 | 980 | 60 | 50 | |

| 4000 | 0.35 | 0.15 | 840 | 50 | 80 | |

| 5000 | 0.28 | 0.11 | 740 | 50 | 100 |

| Type | 30/40 | 40/50 | 40/63 | 50/75 | 50/90 | 63/90 | 63/110 | 75/130 |

| Dimension | ||||||||

| A | 70 | 80 | 100 | 120 | 140 | 140 | 170 | 200 |

| B | 20 | 23 | 23 | 30 | 30 | 40 | 40 | 50 |

| C | 100 | 120 | 144 | 172 | 207 | 207 | 252.5 | 292.5 |

| C1 | 80 | 100 | 100 | 120 | 120 | 144 | 144 | 172 |

| D | 19 | 25 | 25 | 28 | 35 | 35 | 42 | 45 |

| D1 | 9 | 11 | 11 | 14 | 14 | 19 | 19 | 24 |

| E | 121.5 | 144 | 174 | 205 | 238 | 238 | 295 | 335 |

| F | 43 | 49 | 67 | 72 | 74 | 74 | - | - |

| Type | 30/40 | 40/50 | 40/63 | 50/75 | 50/90 | 63/90 | 63/110 | 75/130 |

| Dimension | ||||||||

| G | 70 | 80 | 95 | 112.5 | 137 | 137 | 160 | 180 |

| G1 | 78 | 92 | 112 | 120 | 140 | 140 | 155 | 170 |

| G2 | 50 | 54 | 54 | 64 | 64 | 75.5 | 72.5 | 90 |

| H | 50 | 60 | 72 | 86 | 103 | 103 | 127.5 | 147.5 |

| H1 | 40 | 50 | 50 | 60 | 60 | 72 | 72 | 86 |

| I | 40 | 50 | 63 | 75 | 90 | 90 | 110 | 130 |

| I1 | 30 | 40 | 40 | 50 | 50 | 63 | 63 | 75 |

| L | 71 | 85 | 103 | 112 | 112 | 112 | 142 | 154 |

| M | 75 | 85 | 95 | 115 | 130 | 130 | 165 | 215 |

| N | 60 | 70 | 80 | 95 | 110 | 110 | 130 | 180 |

| Type | 30/40 | 40/50 | 40/63 | 50/75 | 50/90 | 63/90 | 63/110 | 75/130 |

| Dimension | ||||||||

| N1 | 37 | 43.5 | 53 | 57 | 67 | 67 | 74 | 80.5 |

| N2 | 29 | 37 | 37 | 43.5 | 43.5 | 53 | 53 | 57 |

| O | 7 | 9 | 9 | 11 | 13 | 13 | 14 | 16 |

| P | 87 | 100 | 110 | 140 | 160 | 160 | 200 | 250 |

| Q | 56 | 64 | 80 | 93 | 102 | 102 | 125 | 140 |

| R | 71.5 | 84 | 102 | 119 | 135 | 135 | 167.5 | 187.5 |

| R1 | 57 | 71.5 | 71.5 | 84 | 84 | 102 | 102 | 119 |

| S | 6.5 | 7 | 8 | 10 | 12 | 12 | 14 | 15 |

| V | 34 | 40 | 50 | 60 | 70 | 70 | 85 | 100 |

| Z | 122 | 139 | 151 | 174 | 197 | 206.5 | 226 | 250 |

| K | 60 | 70 | 85 | 90 | 110 | 110 | 115 | 120 |

| KE | 4-M6 | 8-M8 | 8-M8 | 8-M8 | 8-M10 | 8-M10 | 8-M10 | 8-M10 |

| a | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| KA | 67.5 | 90 | 97 | 111 | 133 | 133 | 139 | 151 |

| KB | 7 | 9 | 10 | 13 | 13 | 13 | 15 | 15 |

| KC | 3.5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 |

| a1 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| KM | 87 | 90 | 150 | 165 | 175 | 175 | 230 | 255 |

| KN(H8) | 60 | 70 | 115 | 130 | 152 | 152 | 170 | 180 |

| KO | 4-F 9 | 4-F 11 | 4-F 11 | 4-F 14 | 4-F 14 | 4-F 14 | 8-F 14 | 8-F 16 |

| KP | 110 | 125 | 180 | 200 | 210 | 210 | 280 | 320 |

| KQ | 95 | 110 | 142 | 170 | 200 | 200 | 250 | 290 |

| b | 6 | 8 | 8 | 8 | 10 | 10 | 12 | 14 |

| b1 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 8 |

| f | M5 | M5 | M5 | M6 | M6 | M8 | M8 | M10 |

| t | 21.8 | 28.3 | 28.3 | 31.3 | 38.3 | 38.3 | 45.3 | 48.8 |

| t1 | 10.2 | 12.5 | 12.5 | 16 | 16 | 21.5 | 21.5 | 27 |

Plot No. 133-C, Tribhuvan Industrial Estate, Road No. 8, Kathwada G.I.D.C., Ahmedabad - 382430 Gujarat (INDIA)

Mr. Neeraj Bhatia

+91 - 7573884058

Copyrightę2016, N. S. TECHNOCRATS PVT. LTD. , All Right Reserved.